Pulley Bearing Consequences . severe brinell marks can cause premature fatigue failure. typical bearing failure cases are discussed. minimise the risk of conveyor pulley bearing failure with prok’s expert tips. According to statistical results, wear and fatigue are the most. Any static overload or severe impact can cause brinelling. Find out how alignment, contamination, sealing, and coating can. when bearings show signs of wear or damage, replace them promptly to avoid costly downtime and potential equipment damage. Flaking is a phenomenon when material is removed in flakes from a surface layer of the bearing raceways or.

from iskbearing.com

minimise the risk of conveyor pulley bearing failure with prok’s expert tips. when bearings show signs of wear or damage, replace them promptly to avoid costly downtime and potential equipment damage. typical bearing failure cases are discussed. Any static overload or severe impact can cause brinelling. Find out how alignment, contamination, sealing, and coating can. severe brinell marks can cause premature fatigue failure. Flaking is a phenomenon when material is removed in flakes from a surface layer of the bearing raceways or. According to statistical results, wear and fatigue are the most.

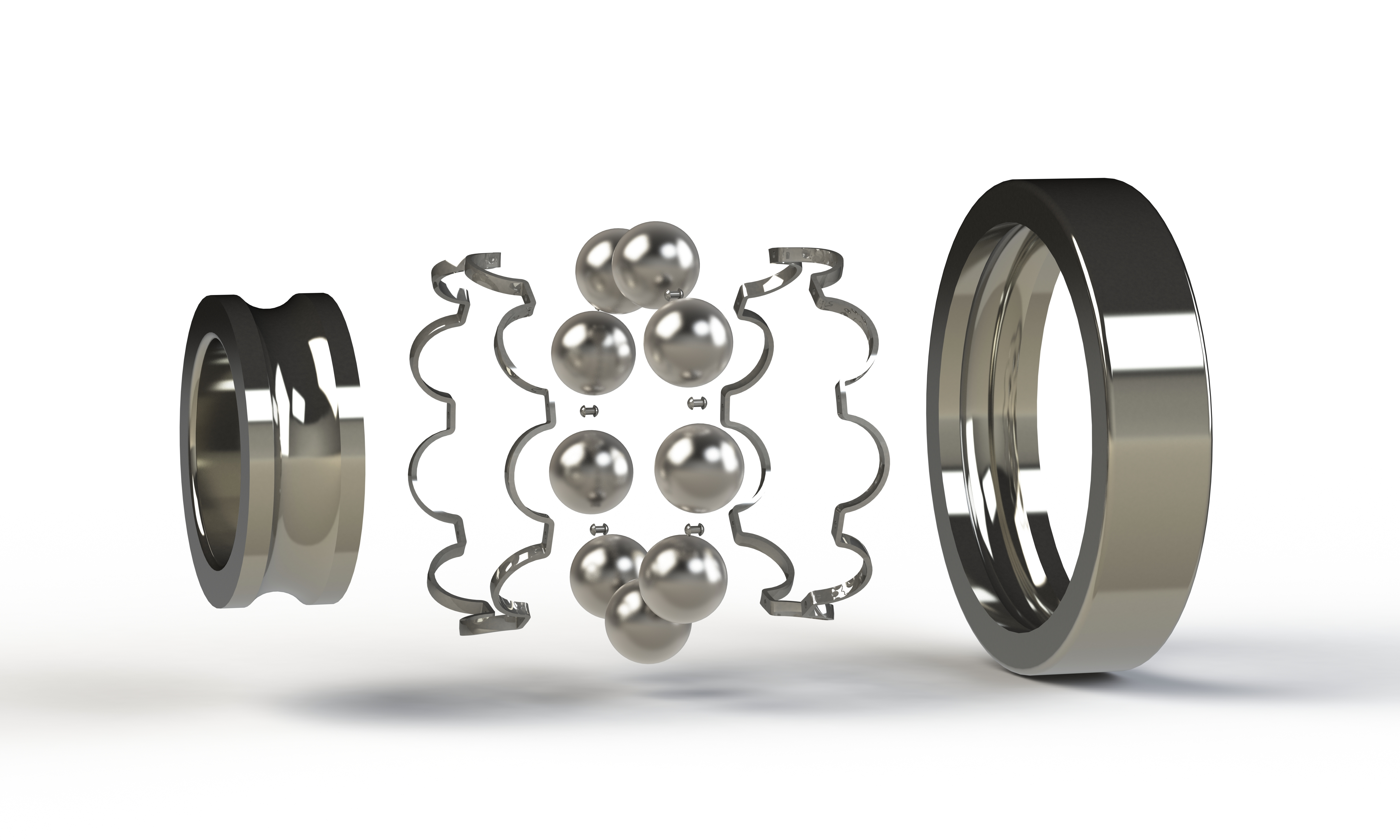

Types of Wheel Bearings All Need to Know about Wheel Bearing ISK

Pulley Bearing Consequences typical bearing failure cases are discussed. According to statistical results, wear and fatigue are the most. minimise the risk of conveyor pulley bearing failure with prok’s expert tips. when bearings show signs of wear or damage, replace them promptly to avoid costly downtime and potential equipment damage. Find out how alignment, contamination, sealing, and coating can. typical bearing failure cases are discussed. Flaking is a phenomenon when material is removed in flakes from a surface layer of the bearing raceways or. Any static overload or severe impact can cause brinelling. severe brinell marks can cause premature fatigue failure.

From www.chegg.com

Solved System Description The system is made of a shaft with Pulley Bearing Consequences severe brinell marks can cause premature fatigue failure. typical bearing failure cases are discussed. Any static overload or severe impact can cause brinelling. when bearings show signs of wear or damage, replace them promptly to avoid costly downtime and potential equipment damage. minimise the risk of conveyor pulley bearing failure with prok’s expert tips. Flaking is. Pulley Bearing Consequences.

From mbworld.org

DIY SC Idler Pulley Bearing repair Forums Pulley Bearing Consequences minimise the risk of conveyor pulley bearing failure with prok’s expert tips. when bearings show signs of wear or damage, replace them promptly to avoid costly downtime and potential equipment damage. Any static overload or severe impact can cause brinelling. severe brinell marks can cause premature fatigue failure. Find out how alignment, contamination, sealing, and coating can.. Pulley Bearing Consequences.

From mbworld.org

DIY SC Idler Pulley Bearing repair Forums Pulley Bearing Consequences Find out how alignment, contamination, sealing, and coating can. Any static overload or severe impact can cause brinelling. According to statistical results, wear and fatigue are the most. Flaking is a phenomenon when material is removed in flakes from a surface layer of the bearing raceways or. typical bearing failure cases are discussed. minimise the risk of conveyor. Pulley Bearing Consequences.

From www.chegg.com

Solved Both pulleys are fixed to the shaft and as the shaft Pulley Bearing Consequences minimise the risk of conveyor pulley bearing failure with prok’s expert tips. Flaking is a phenomenon when material is removed in flakes from a surface layer of the bearing raceways or. typical bearing failure cases are discussed. Find out how alignment, contamination, sealing, and coating can. severe brinell marks can cause premature fatigue failure. Any static overload. Pulley Bearing Consequences.

From www.scribd.com

Pulley Bearing (Mechanical) Aluminium Pulley Bearing Consequences Any static overload or severe impact can cause brinelling. when bearings show signs of wear or damage, replace them promptly to avoid costly downtime and potential equipment damage. minimise the risk of conveyor pulley bearing failure with prok’s expert tips. According to statistical results, wear and fatigue are the most. Flaking is a phenomenon when material is removed. Pulley Bearing Consequences.

From www.youtube.com

️Installing A Bearing Into A Pulley "How To"🔧 YouTube Pulley Bearing Consequences severe brinell marks can cause premature fatigue failure. Any static overload or severe impact can cause brinelling. minimise the risk of conveyor pulley bearing failure with prok’s expert tips. Find out how alignment, contamination, sealing, and coating can. According to statistical results, wear and fatigue are the most. Flaking is a phenomenon when material is removed in flakes. Pulley Bearing Consequences.

From www.chegg.com

Solved 583. Both pulleys are fixed to the shaft and as the Pulley Bearing Consequences Flaking is a phenomenon when material is removed in flakes from a surface layer of the bearing raceways or. Any static overload or severe impact can cause brinelling. severe brinell marks can cause premature fatigue failure. Find out how alignment, contamination, sealing, and coating can. when bearings show signs of wear or damage, replace them promptly to avoid. Pulley Bearing Consequences.

From www.chegg.com

Solved Both pulleys are fixed to the shaft and as the shaft Pulley Bearing Consequences severe brinell marks can cause premature fatigue failure. minimise the risk of conveyor pulley bearing failure with prok’s expert tips. According to statistical results, wear and fatigue are the most. Flaking is a phenomenon when material is removed in flakes from a surface layer of the bearing raceways or. when bearings show signs of wear or damage,. Pulley Bearing Consequences.

From www.nskbearingcatalogue.com

A damaged tensioner pulley bearing will affect the normal use of the car Pulley Bearing Consequences severe brinell marks can cause premature fatigue failure. Flaking is a phenomenon when material is removed in flakes from a surface layer of the bearing raceways or. According to statistical results, wear and fatigue are the most. when bearings show signs of wear or damage, replace them promptly to avoid costly downtime and potential equipment damage. minimise. Pulley Bearing Consequences.

From www.svtperformance.com

HOWTO replace an idler/tensioner pulley bearing.. Pulley Bearing Consequences Flaking is a phenomenon when material is removed in flakes from a surface layer of the bearing raceways or. Find out how alignment, contamination, sealing, and coating can. Any static overload or severe impact can cause brinelling. severe brinell marks can cause premature fatigue failure. typical bearing failure cases are discussed. According to statistical results, wear and fatigue. Pulley Bearing Consequences.

From www.youtube.com

Idler Pulley Bearing Change , For Most Mowers , Cheaper than buying the Pulley Bearing Consequences minimise the risk of conveyor pulley bearing failure with prok’s expert tips. Find out how alignment, contamination, sealing, and coating can. typical bearing failure cases are discussed. According to statistical results, wear and fatigue are the most. severe brinell marks can cause premature fatigue failure. Flaking is a phenomenon when material is removed in flakes from a. Pulley Bearing Consequences.

From pmmonline.co.uk

Premature failure guide pulley bearings Professional Motor Mechanic Pulley Bearing Consequences minimise the risk of conveyor pulley bearing failure with prok’s expert tips. Any static overload or severe impact can cause brinelling. severe brinell marks can cause premature fatigue failure. According to statistical results, wear and fatigue are the most. typical bearing failure cases are discussed. Flaking is a phenomenon when material is removed in flakes from a. Pulley Bearing Consequences.

From www.youtube.com

How To Replace Idler Pulley Bearings YouTube Pulley Bearing Consequences minimise the risk of conveyor pulley bearing failure with prok’s expert tips. when bearings show signs of wear or damage, replace them promptly to avoid costly downtime and potential equipment damage. Find out how alignment, contamination, sealing, and coating can. According to statistical results, wear and fatigue are the most. severe brinell marks can cause premature fatigue. Pulley Bearing Consequences.

From www.savacable.com

CP Series Pulley, Plated Steel, Ball Bearing Sava Pulley Bearing Consequences when bearings show signs of wear or damage, replace them promptly to avoid costly downtime and potential equipment damage. According to statistical results, wear and fatigue are the most. Any static overload or severe impact can cause brinelling. severe brinell marks can cause premature fatigue failure. minimise the risk of conveyor pulley bearing failure with prok’s expert. Pulley Bearing Consequences.

From www.chegg.com

Solved Problem The figure shows a shaft mounted in bearings Pulley Bearing Consequences Any static overload or severe impact can cause brinelling. Flaking is a phenomenon when material is removed in flakes from a surface layer of the bearing raceways or. when bearings show signs of wear or damage, replace them promptly to avoid costly downtime and potential equipment damage. minimise the risk of conveyor pulley bearing failure with prok’s expert. Pulley Bearing Consequences.

From quizlet.com

The rope and pulley have negligible mass, and the pulley is Quizlet Pulley Bearing Consequences Any static overload or severe impact can cause brinelling. Find out how alignment, contamination, sealing, and coating can. typical bearing failure cases are discussed. According to statistical results, wear and fatigue are the most. minimise the risk of conveyor pulley bearing failure with prok’s expert tips. severe brinell marks can cause premature fatigue failure. Flaking is a. Pulley Bearing Consequences.

From iskbearing.com

Types of Wheel Bearings All Need to Know about Wheel Bearing ISK Pulley Bearing Consequences Flaking is a phenomenon when material is removed in flakes from a surface layer of the bearing raceways or. According to statistical results, wear and fatigue are the most. typical bearing failure cases are discussed. Find out how alignment, contamination, sealing, and coating can. minimise the risk of conveyor pulley bearing failure with prok’s expert tips. when. Pulley Bearing Consequences.

From news.bgautomotive.co.uk

9 Common Symptoms Of A Bad Crankshaft Pulley BGA NEWS Pulley Bearing Consequences minimise the risk of conveyor pulley bearing failure with prok’s expert tips. Flaking is a phenomenon when material is removed in flakes from a surface layer of the bearing raceways or. severe brinell marks can cause premature fatigue failure. Find out how alignment, contamination, sealing, and coating can. when bearings show signs of wear or damage, replace. Pulley Bearing Consequences.